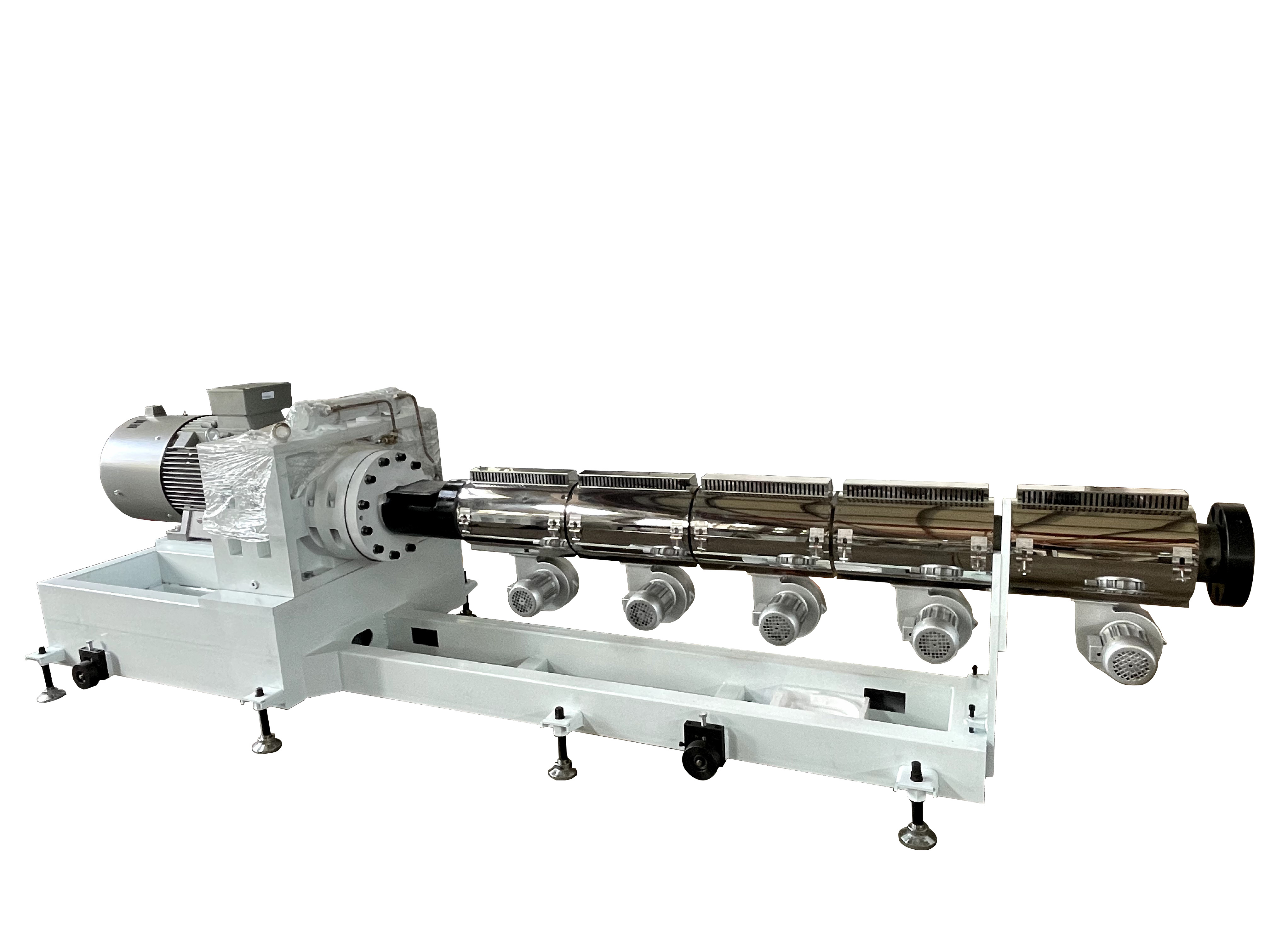

High capacity and low energy consumption extruder

Category: Component

Product Details

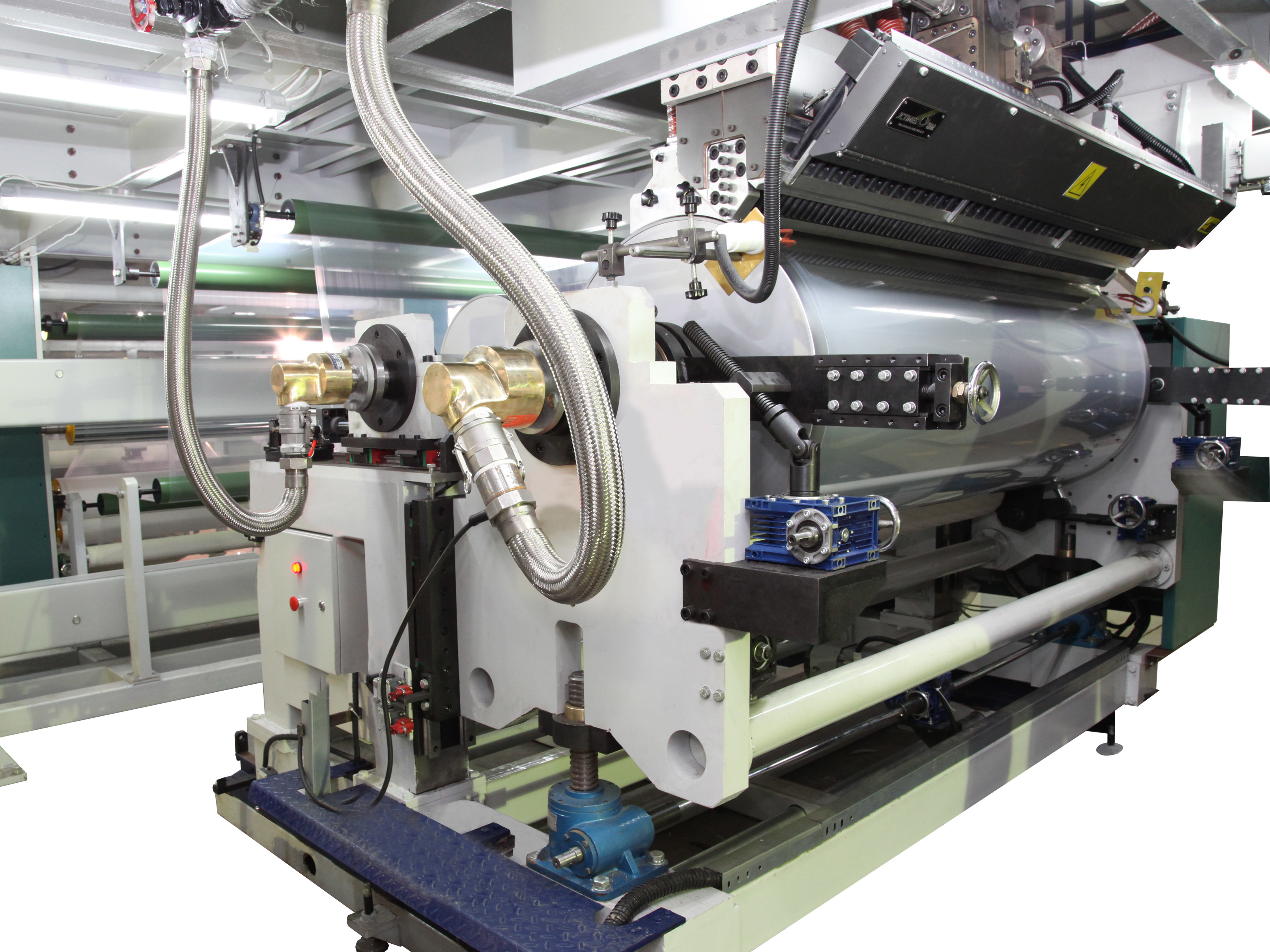

1. Barrel and screw material: 38CrMoAlA, barrel and screw hardness: HRC-750 or above, containing shear and diamond-shaped mixing section and special hardening treatment, not only has good corrosion and abrasion resistance, but also has the advantages of high output, low energy consumption and good plasticization.

2. The extruder is equipped with digital intelligent pressure display, which shows the melt pressure and temperature inside the extruder at any time.

3. The heating of the body adopts ceramic heating ring or cast aluminum heating ring, equipped with forced air cooling device, and the feeding section is cooled by circulating water.

4. gearbox gear material adopts 20CrMnTi after surface carburizing treatment and high precision grinding and processing (including external circulating oil lubrication system), the gearbox is equipped with strong thrust bearing, high torque output.

5. Quick screen changer can choose manual screen changer or hydraulic non-stop quick screen changer, reduce the waste of raw materials, can ensure the production capacity of the whole machine.

| Extruder Model | SJ45 | SJ50 | SJ55 | SJ65 | SJ75 | SJ80 | SJ85 | SJ90 | SJ120 | SJ150 |

|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter (mm) | 45 | 50 | 55 | 65 | 75 | 80 | 85 | 90 | 120 | 150 |

| L/D ratio | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 |

| Motor power | 22kw | 22kw | 30kw | 37kw | 55kw | 75kw | 75kw | 90kw | 120kw | 160kw |

Product Video

Promotion Video 2023

Successful Cases

Cotton Packaging Film

Forage Silage Film

greenhouse film

geomembrane

FFS Repackaging Film

Container inner wrap

Cold Stretch Casing Film

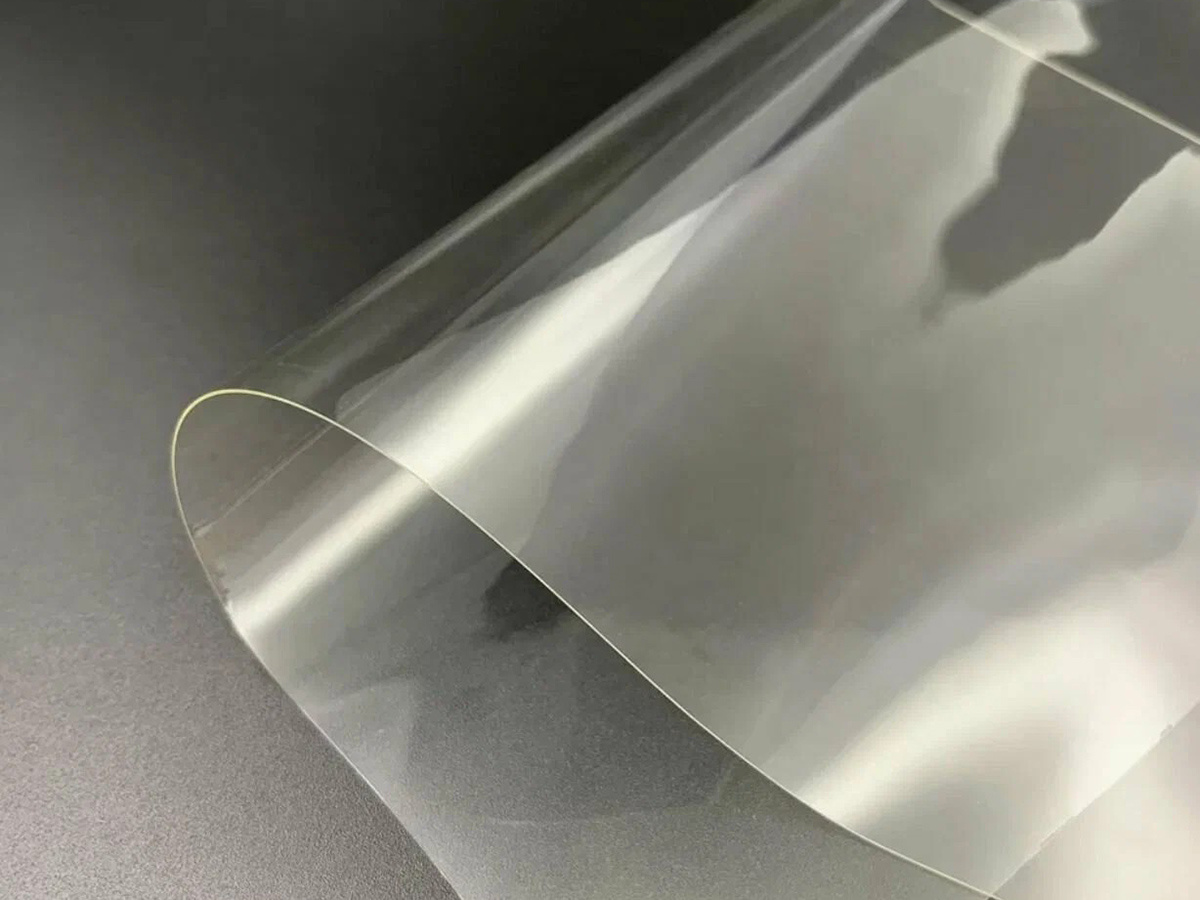

Metal protective film

heat shrink film

Food Packaging Film

Eisai packaging film

Eisai Breathable Film

courier bag film

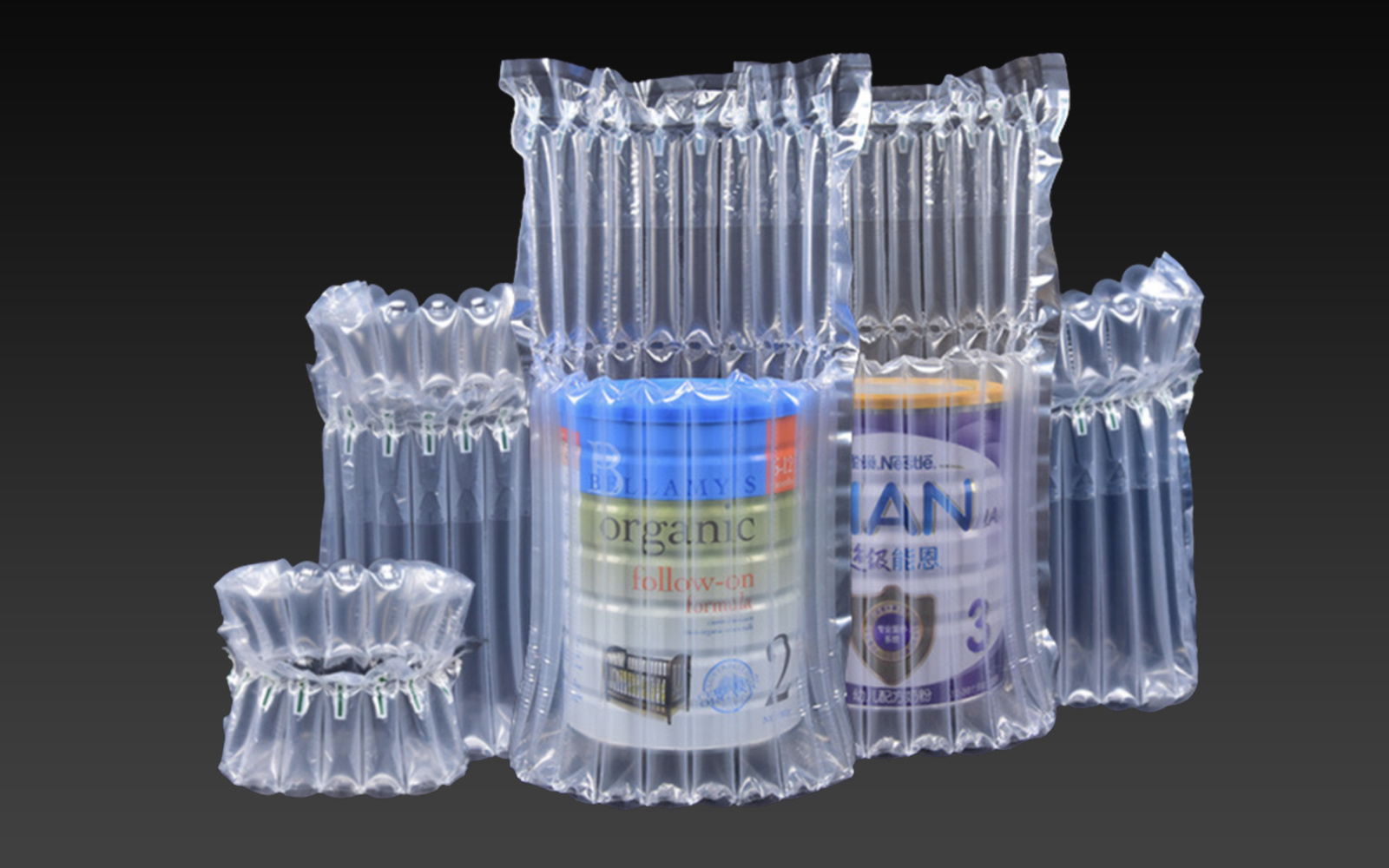

Cylinder bag film

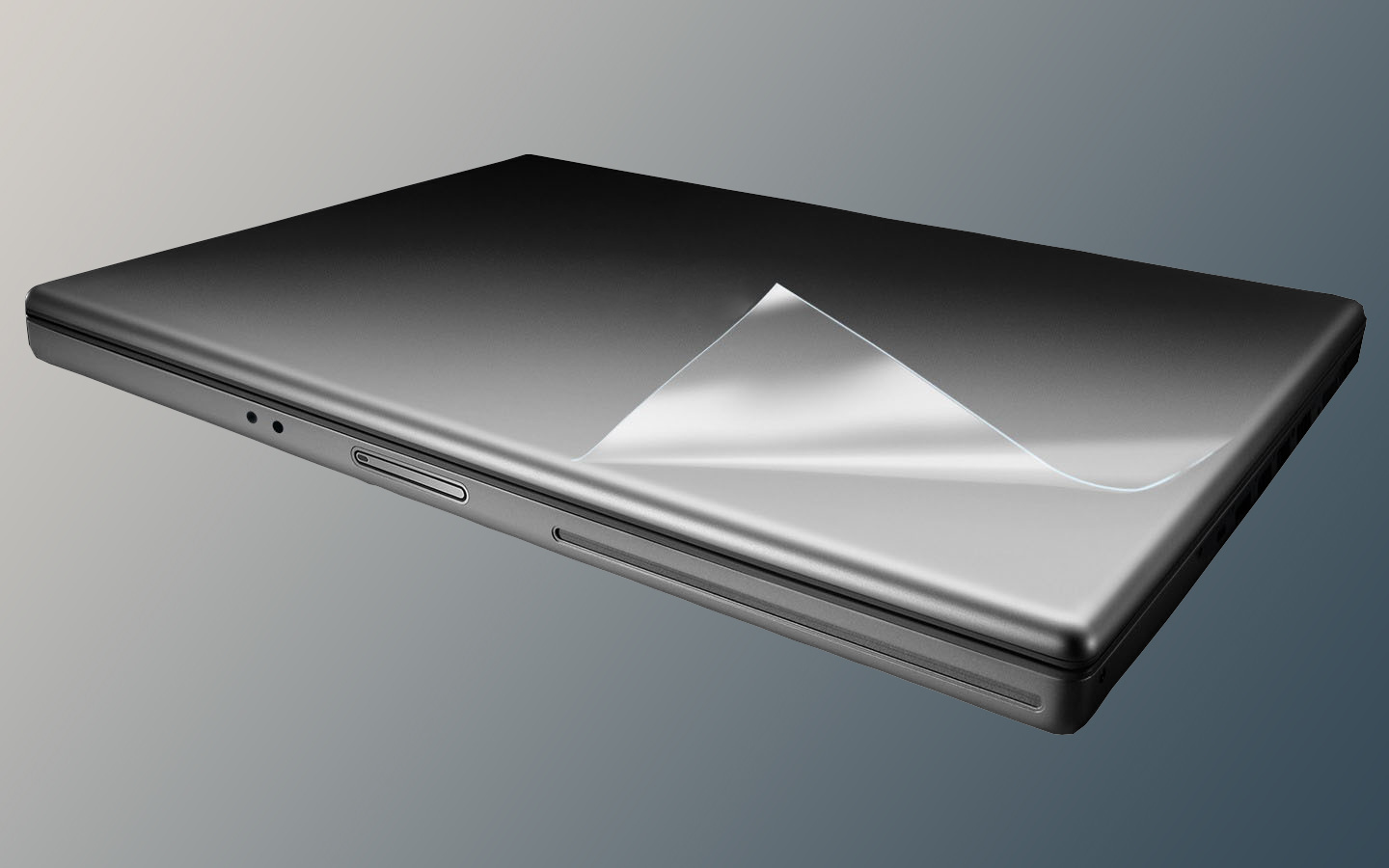

Electronic protective film

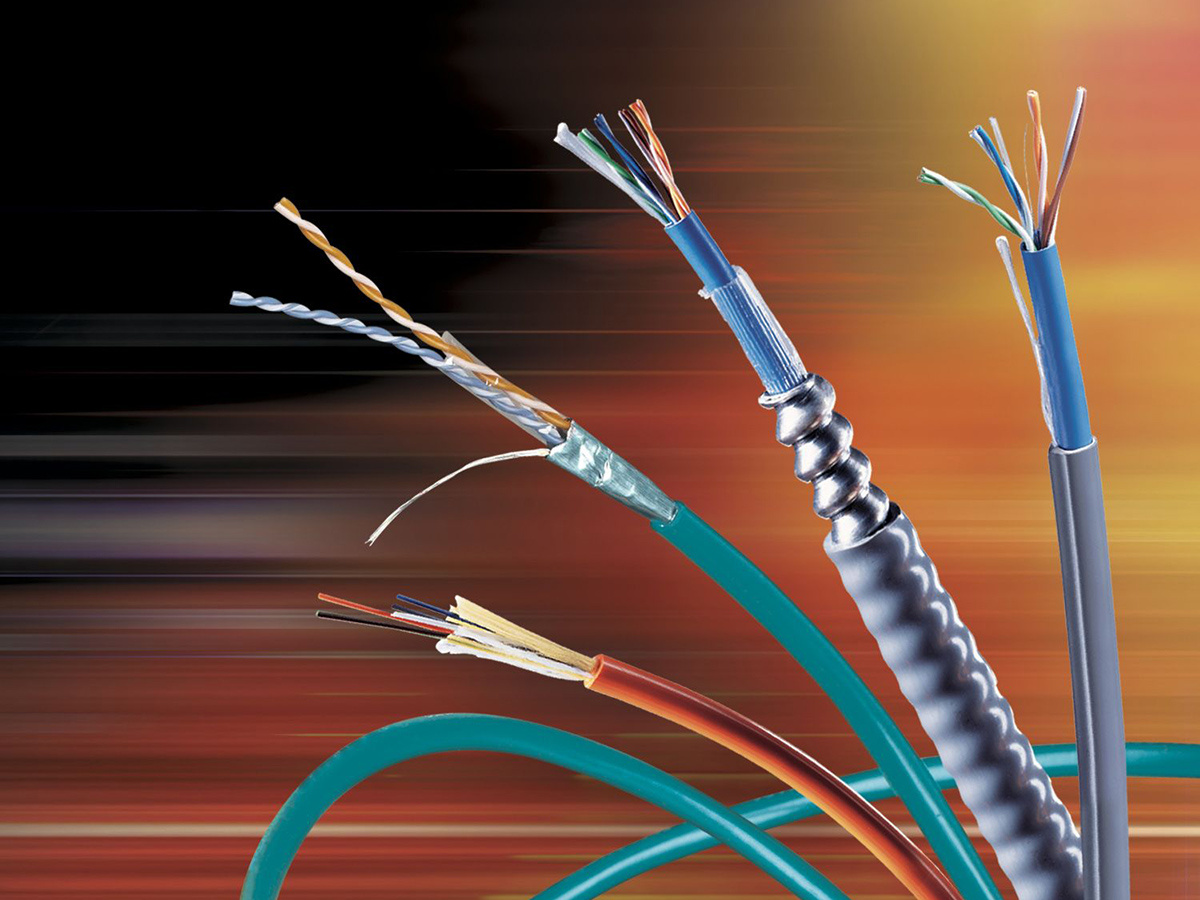

Communication cable protection film

EVA film

LCP film

Photovoltaic backsheet film

Product Consulting

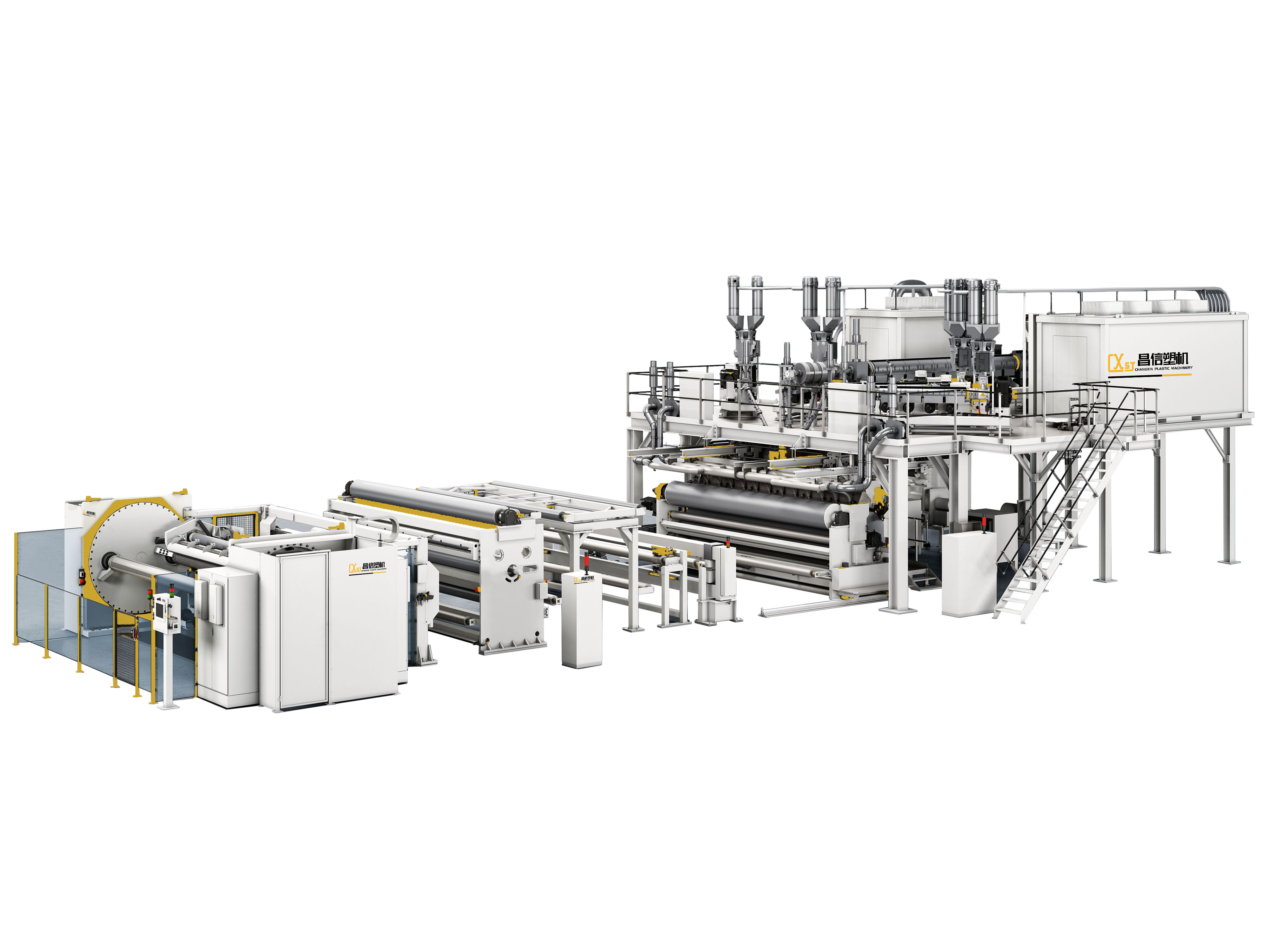

Wuhan Changxin Plastic Machine Co., Ltd. was established in 1995, the company is committed to all kinds of plastic film machinery research and development design and manufacturing. All kinds of film production lines we produce sell well all over the country, and are exported to Canada, Chile, New Zealand, Pakistan, Malaysia and other dozens of countries, and win the praise of customers with excellent quality and intimate after-sales.

Keyword:

extruder

energy

changer

Previous: Die head