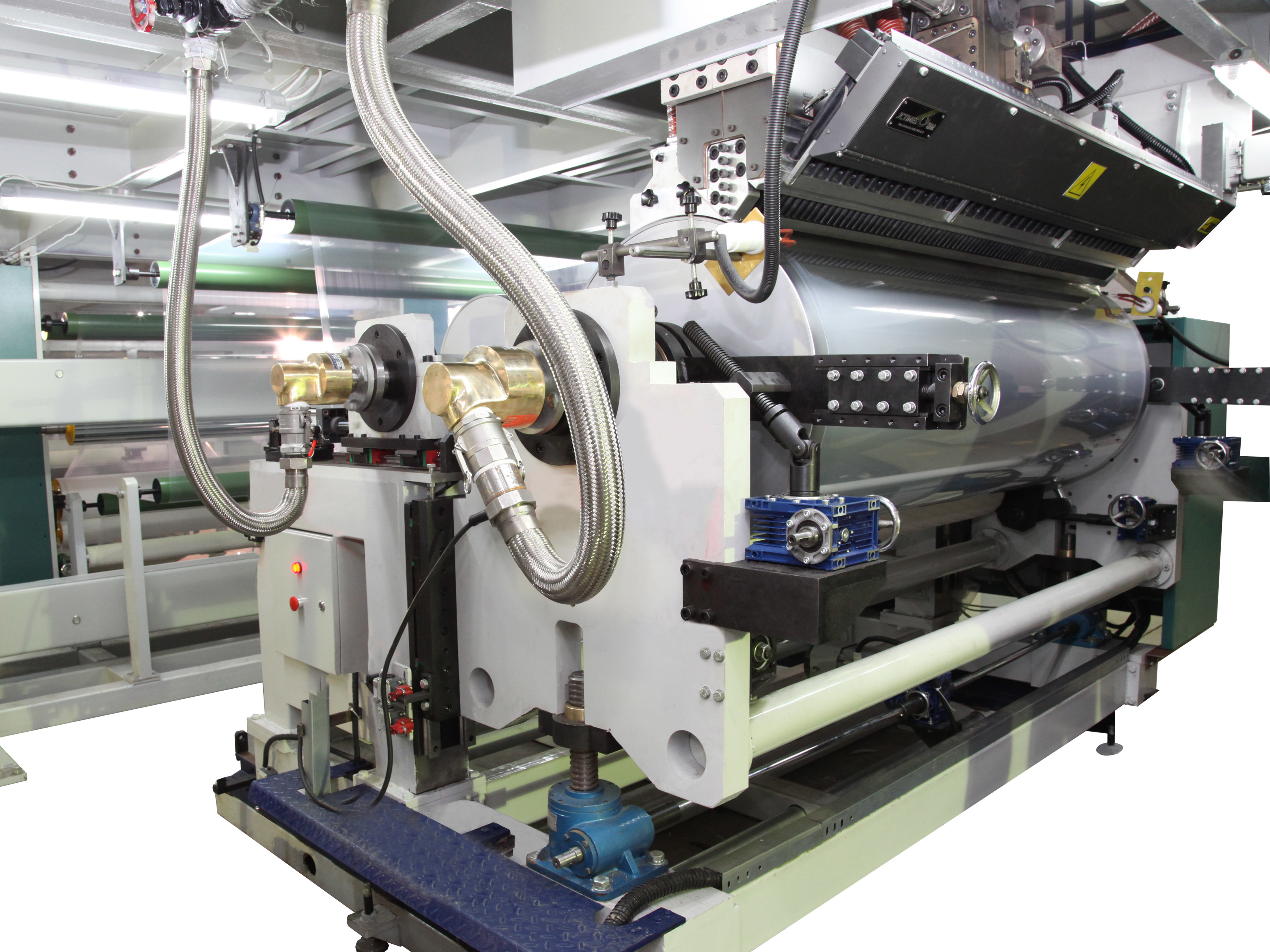

Die head

Category: Component

Product Details

molds

As the most core part of blown film equipment, it directly affects the quality of film products. We have been engaged in the design and development of blown film molds for more than 20 years, through the study of the processing characteristics of various types of polymer materials and their rheological principles, combined with certain computer simulation design, we continue to optimize our mold runner structure and melt feed port, so that the melt in order to ensure excellent fluidity while ensuring that the thermoplasticity of the resin. The unique design allows the film products to have extremely low thickness tolerance, good visual effect, high output and other characteristics.

Processing

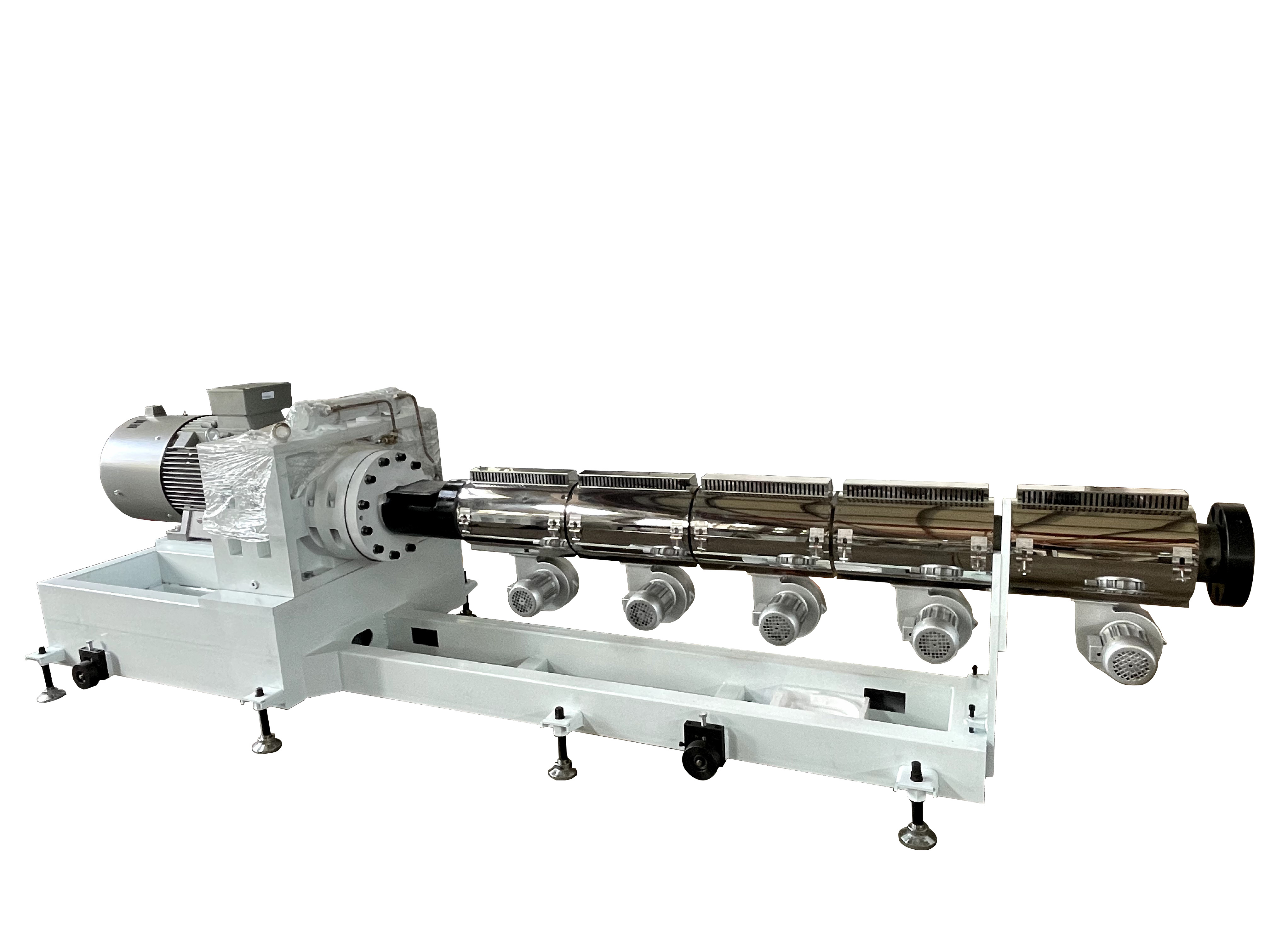

We use imported 5-axis machining centers to process the molds you buy in depth, and according to different types of molds with different grades of high-precision mold steel.

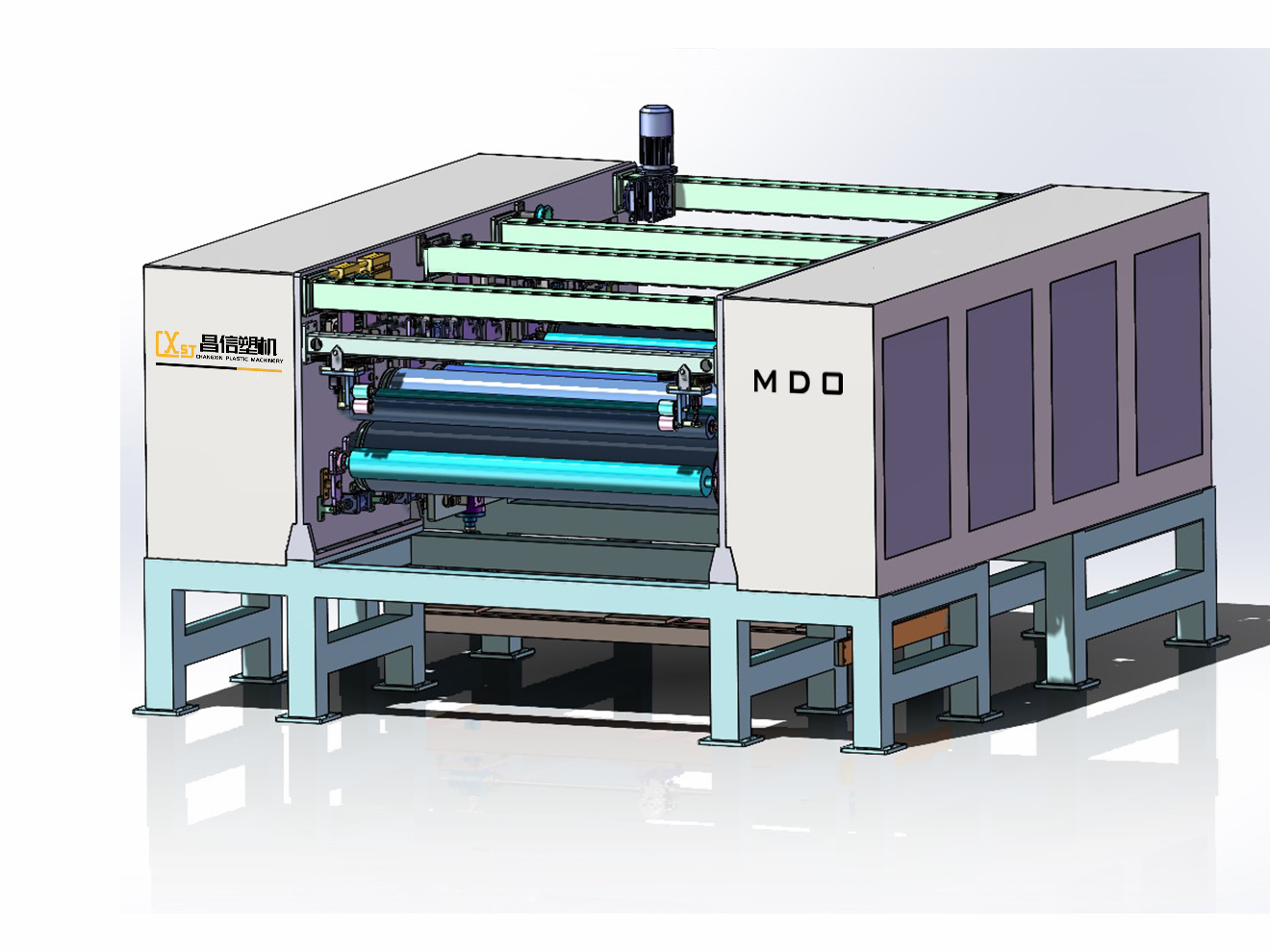

Wide range of molds to choose from

※ Single layer rotary/internal cooling PE molds

Single layer LCP mold

※ Two-layer co-extrusion rotary/internal cooling PE molds

※ Three-layer co-extrusion rotary/internal cooling molds

※ Three-layer co-extruded non-crystalline film die (low center feed)

※ Three-layer co-extrusion mold for self-adhesive film

※ Five-layer co-extrusion PE mold

※ 5-layer and 7-layer co-extruded PA high barrier film molds (conical stacking/planar stacking)

Product Video

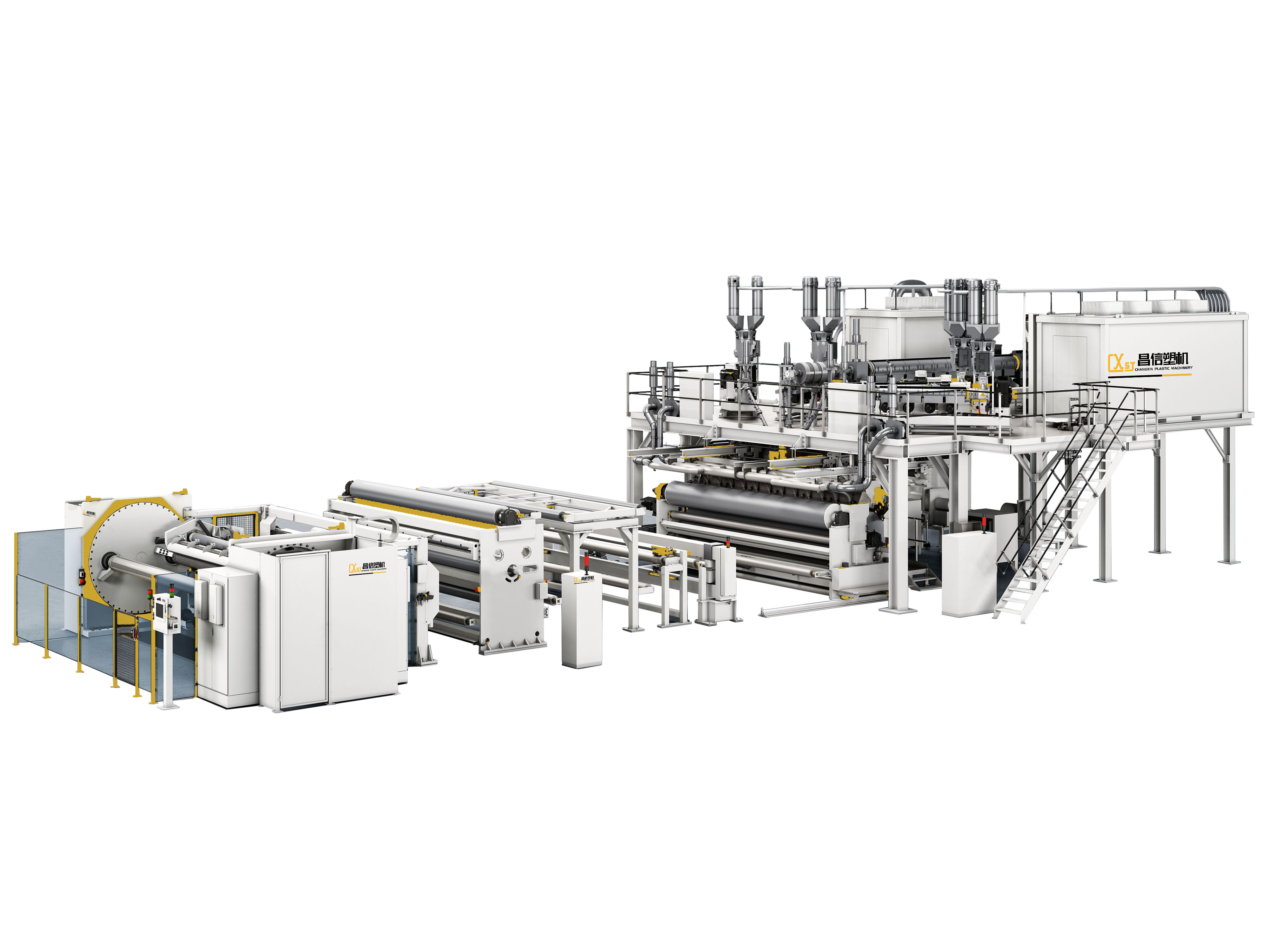

Company Product Introduction

Successful Cases

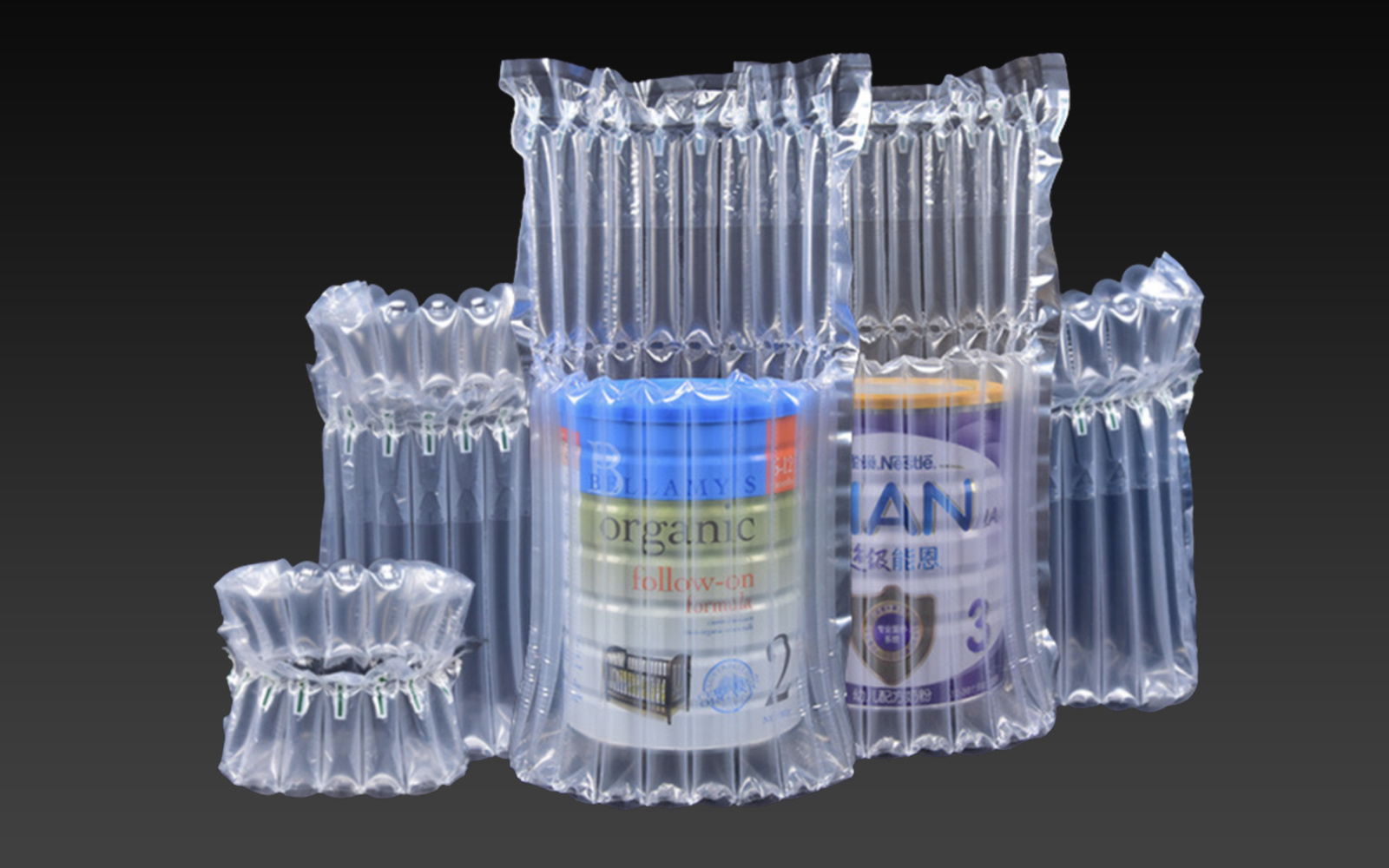

Cotton Packaging Film

Forage Silage Film

greenhouse film

geomembrane

FFS Repackaging Film

Container inner wrap

Cold Stretch Casing Film

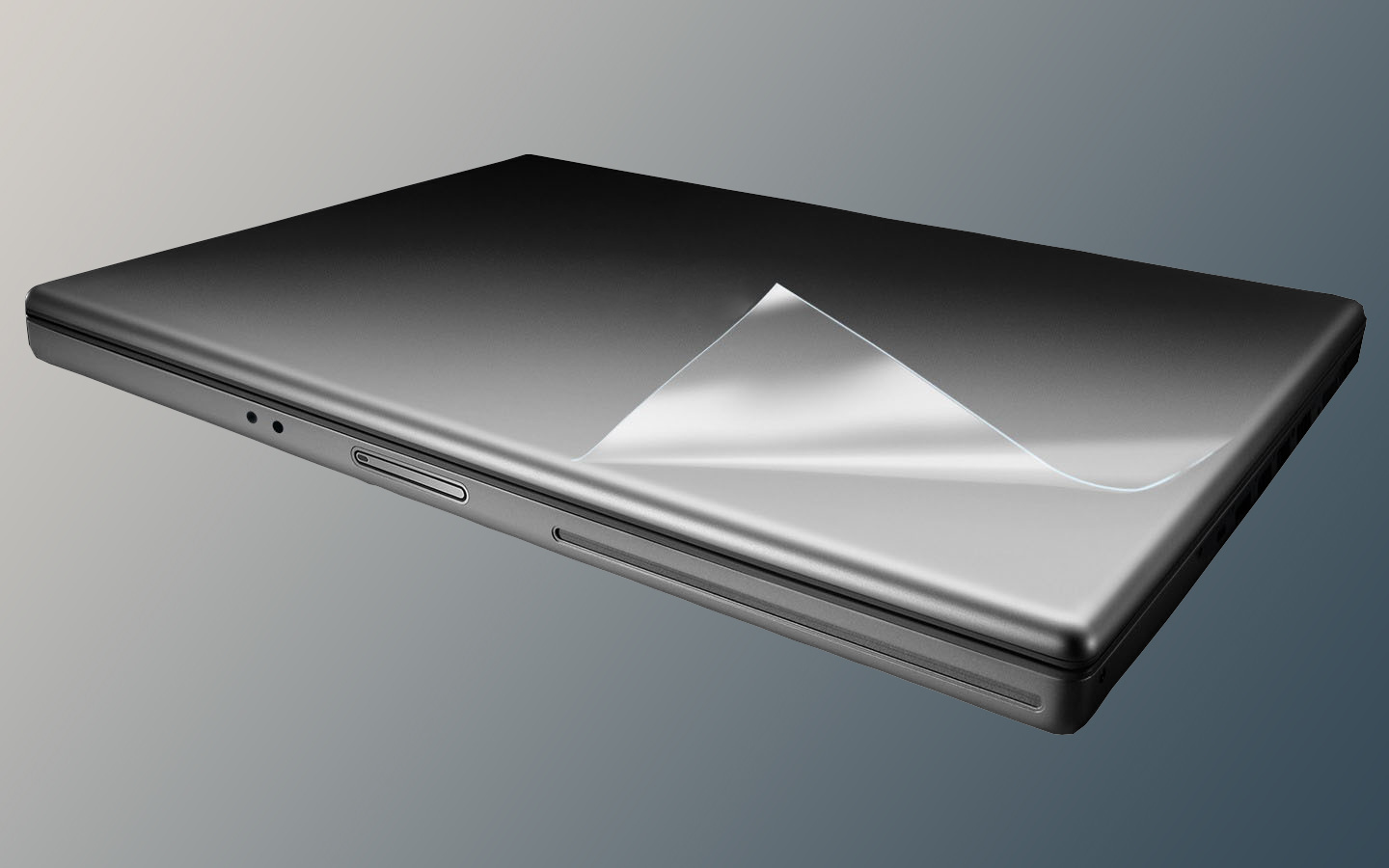

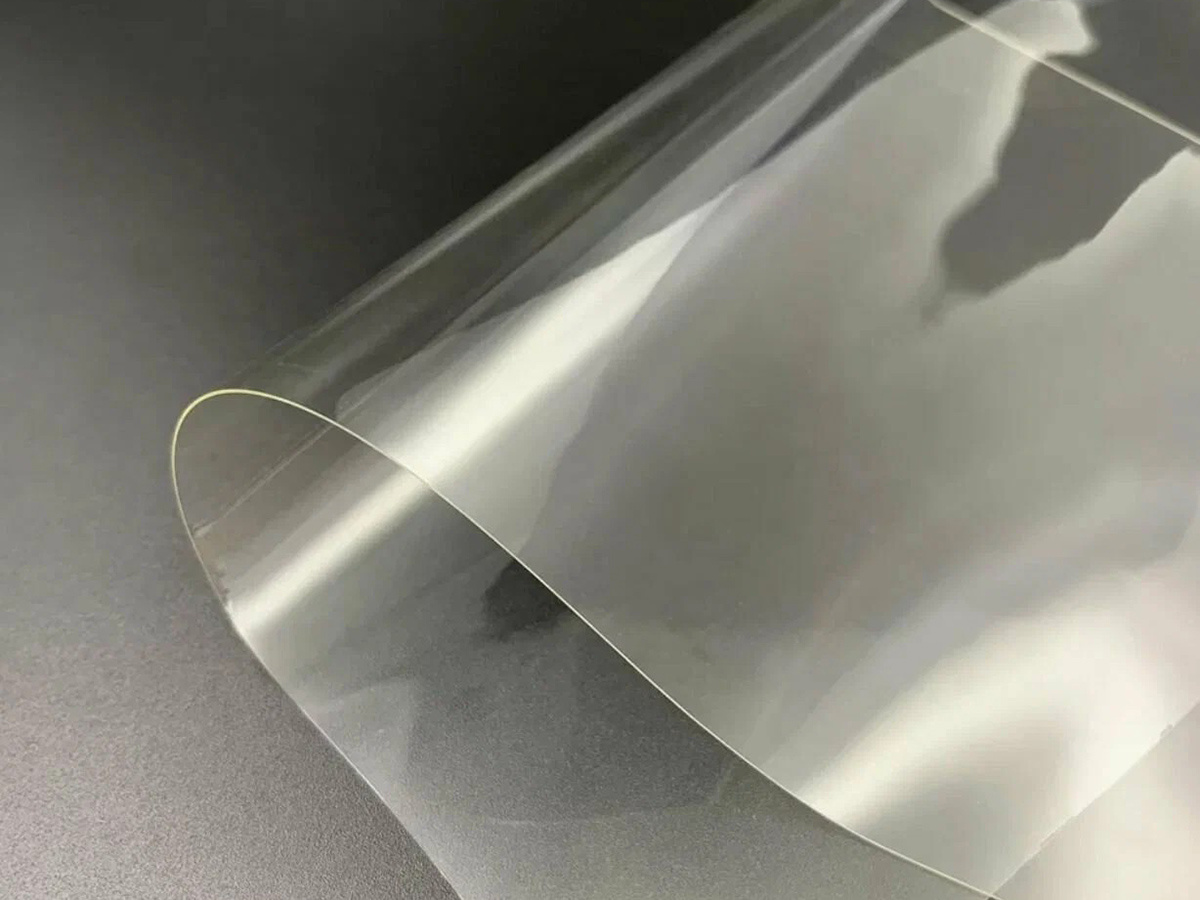

Metal protective film

heat shrink film

Food Packaging Film

Eisai packaging film

Eisai Breathable Film

courier bag film

Cylinder bag film

Electronic protective film

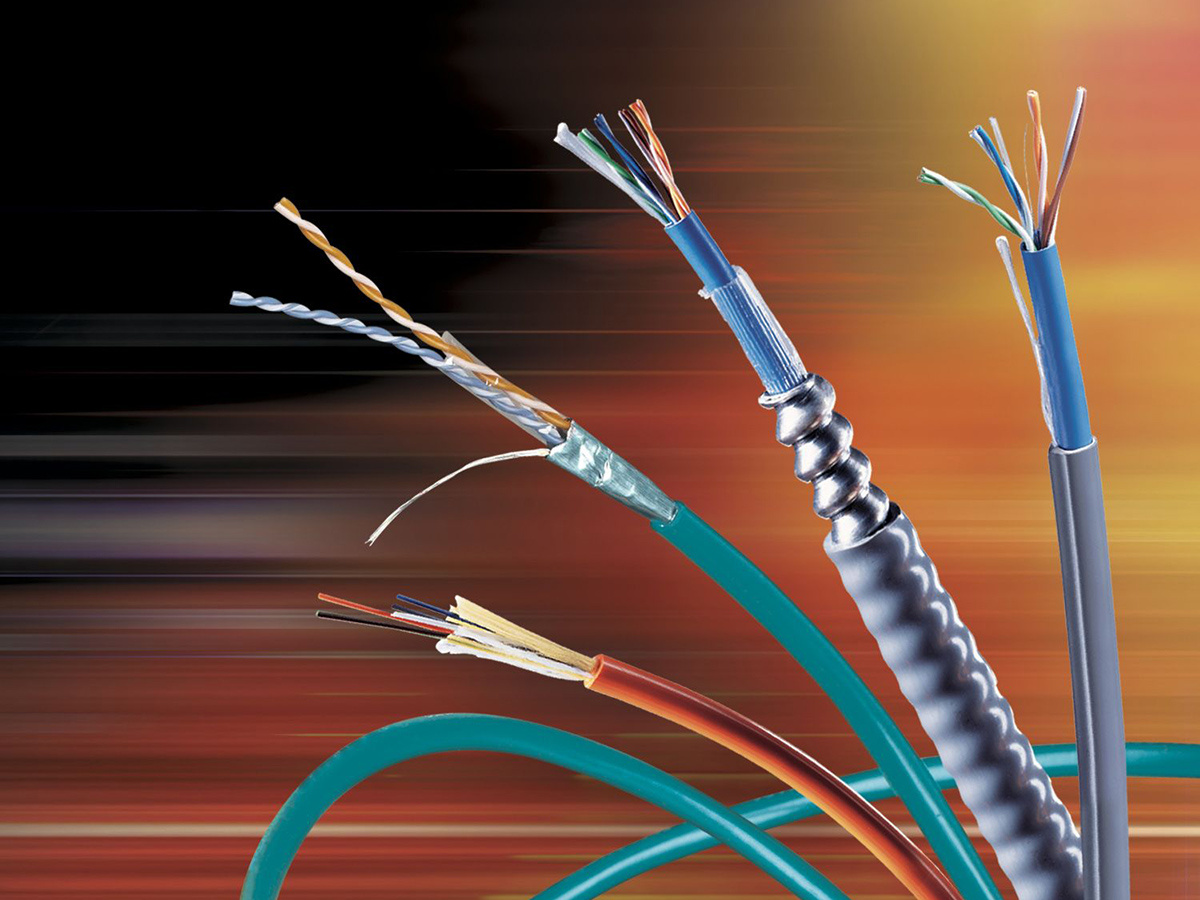

Communication cable protection film

EVA film

LCP film

Photovoltaic backsheet film

Product Consulting

Wuhan Changxin Plastic Machine Co., Ltd. was established in 1995, the company is committed to all kinds of plastic film machinery research and development design and manufacturing. All kinds of film production lines we produce sell well all over the country, and are exported to Canada, Chile, New Zealand, Pakistan, Malaysia and other dozens of countries, and win the praise of customers with excellent quality and intimate after-sales.

Keyword:

molds

mold

co-extrusion

Previous: No more !